info@shxvalve.com

info@shxvalve.com info@shxvalve.com

info@shxvalve.comTel:+86-17717520739

Email:info@shxvalve.com

Address: NO.720, Suide Road, Jiading District,Shanghai, China.

2022-09-25

What is a jacketed ball valve?

Jacketed ball valve is the ball valve that have jackets that help in heating or cooling the flow media to prevent seizing or crystallization. Jacketed ball valves for heating applications have good heating jackets to provide high-temperature oil or steam over the valve body and ball parts to keep the media in the required state. This is mostly used in media such as liquid sulfur and bitumen. Jacketed ball valves have jackets that cover the body from one flange end to the other flange end. The valve body is altered by adding oversized flanges. For instance, a jacketed ball valve with a nominal diameter of 2-inch would have a flange of 3-inch diameter. The oversize flange helps to allow sufficient bolting clearance space. Jacketed ball valves are used to handle very viscous media that can easily solidify at ambient temperature.

Some of the fluids that can be used as heating media in jacketed ball valves include thermic fluid oil, steam, and hot water. All jacketed ball valves are tested after constructing or welding jackets to the valve body. The standard jacketed ball valve is made using cast carbon steel and stainless steel materials. Jacketed ball valves can also be made of other special materials upon request by the customer. Connections that can be used between the valve and the pipeline include threaded end and flanged end connections. Jacketed ball valves can be operated manually or actuated using valve actuators (electric and pneumatic actuators).

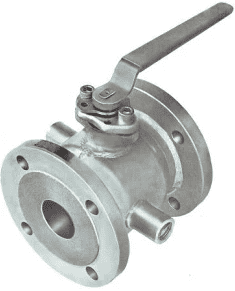

Figure: Jacketed ball valve.

Figure: Jacketed ball valve.

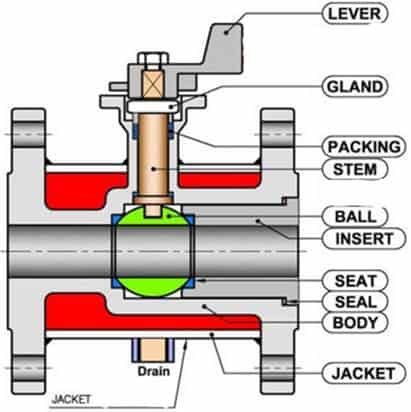

Components of a jacketed ball valve

Valve body

This is the component of a jacketed ball valve that houses all internal parts. The valve body is made of strong materials like carbon steel and stainless steel to enhance valve strength and prevent corrosion. The valve body contains the inlet and outlet ports of the jacketed ball valve. It also contains the inlet and outlet drains of the heating or cooling media.

Actuator/handle

The actuator is a component used for the automatic jacketed ball valve. The actuator is tasked with providing the torque required when the valve needs to open or close. Manual jacketed ball valves use a handle in form of a handwheel or hand lever. The valve operator is required in a manual jacketed ball valve. The operator is responsible for providing the torque required when the valve has to be opened or closed.

Ball

This is the component of a jacketed ball valve that is used to allow or block fluid flow. The ball has a bore at its middle section where fluid flows when it is in the open mode.

Stem

A stem is the component of a jacketed ball valve that is used to connect the valve ball to the actuator or the handle. The stem is responsible for transmitting torque from the actuator/handle to the ball so that the ball can rotate to allow fluid flow or block fluid flow.

Jacket

Jackets are welded or constructed in the valve body so that the media required to heat or cool the fluid can circulate in the valve giving out heat or absorbing heat accordingly.

Seats

Seats are components used in jacketed ball valves to support the ball in its place. Seats are placed between the ball and the body and they also prevent fluid leakage in the body.

Packing

Packing refers to seals used in the valve stem to prevent fluid leakage.

Trim

Trim refers to internal components of the jacketed ball valve such as seats, seating surface, seals, O-rings, and ball.

Figure: Components of a jacketed ball valve.

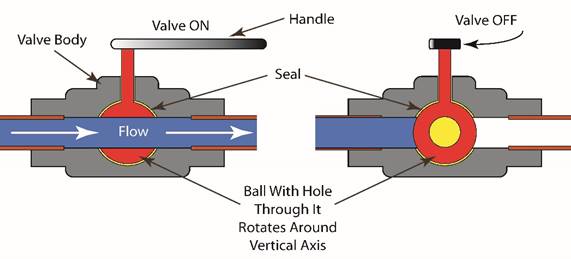

How does a jacketed ball valve work?

Jacketed ball valve works by using a ball with a bore at its middle section. To open a jacketed ball valve, the handle is turned anticlockwise for a quarter turn. The rotary motion applied on the handle for manual valves is transmitted through the valve stem to the valve ball. This makes the ball rotate for the same quarter (90o degrees). When the ball turns 90o degrees it makes the bore collinear with the pipeline. As such, fluid flows through the valve to the next section of the pipeline. The same working principle applies to an actuated jacketed ball valve. The only difference between the actuated and the manual valve is that the actuated one uses an actuator to provide the rotational force needed to open or close the valve. To close the jacketed ball valve, the handle/actuator turns 90o degrees in the clockwise direction which makes the ball rotate in the same direction. This makes the ball bore block the fluid flow as it becomes perpendicular to the pipeline. To ensure the fluid flowing through the valve is kept at the required viscosity, hot media is passed through the valve jackets. This helps to release heat on the media. This heat helps to reduce media viscosity so that it does not stick to the jacketed ball valve or in the pipeline. Such media include very thick bitumen, soap, polymers among others.

Figure: Working of a jacketed ball valve.

Types of jacketed ball valve

One-piece jacketed ball valve

This is a jacketed ball valve which is made up of one piece of cast body. One-piece jacketed ball valves are free from fluid leakage as the valves are tested after being manufactured to ensure the welded joints have no imperfections. One-piece jacketed ball valves are the cheapest valves as they consume less material relative to other valves of the same size. However, single-piece jacketed ball valves cannot be opened for cleaning or repair. These valves are disposed of when they break.

Figure: One-piece jacketed ball valve.

Two-piece jacketed ball valve

This is a jacketed ball valve that consists of two pieces of the body. One of the two pieces has the valve body and one end joint and the other piece consists of the trim and second joint. Two-piece jacketed ball valves can be inspected, cleaned, and repaired while in the field, unlike their single-piece counterparts. However, to repair or clean a two-piece jacketed ball valve the valve must be removed from the pipeline.

Figure: Two-piece jacketed ball valve.

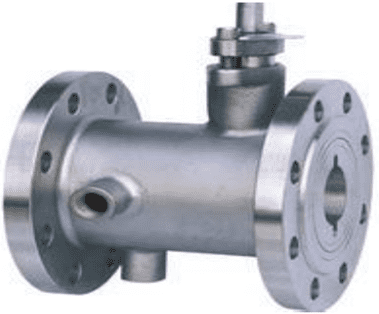

Three-piece jacketed ball valve

A three-piece jacketed ball valve is a ball valve that consists of three pieces. The three pieces are held together using bolts and nuts to form a leakage-free body. Three-piece jacketed ball valves make it possible to remove center components such as stem, ball, and seats from the pipeline without removing the jacketed ball valve from the pipeline. This feature makes a three-piece jacketed ball valve efficient for cleaning accumulated solids, replacement of the ball, gland packing, and seats. However, three-piece jacketed ball valves are more expensive relative to single and two-piece valves.

Figure: Three-piece jacketed ball valve.

Three-way jacketed ball valve

This is a jacketed ball valve with three ports. The three ports are used as either mixing valves or diverting valves. As such there are two configurations of three-way jacketed ball valve that is the L-shaped and the T-shaped type. The L-shaped configuration of a jacketed ball valve is used to divert fluid from one direction to another. The T-shaped configuration of a three way jacketed ball valve is used to mix and divert fluid streams. When the T-shaped configuration is used to mix fluids, it gets two fluid streams from two ports which are mixed and flow out as one fluid stream. When a T-shaped configuration is used to divert fluid, it gets fluid from the inlet port and the fluid is divided into two streams flowing through the two outlet ports.

Figure: Three-way jacketed ball valve.

Features of jacketed ball valve

Applications of jacketed ball valve

Advantages of jacketed ball valve

Disadvantages of jacketed ball valve

Troubleshooting jacketed ball valve

Jacketed ball valve not operating smoothly

Outside fluid leakage

Seat leakage