info@shxvalve.com

info@shxvalve.com info@shxvalve.com

info@shxvalve.comTel:+86-17717520739

Email:info@shxvalve.com

Address: NO.720, Suide Road, Jiading District,Shanghai, China.

2022-11-27

1. Automatic recirculation valve is driven by its own medium, minimum flow protection device of centrifugal pump

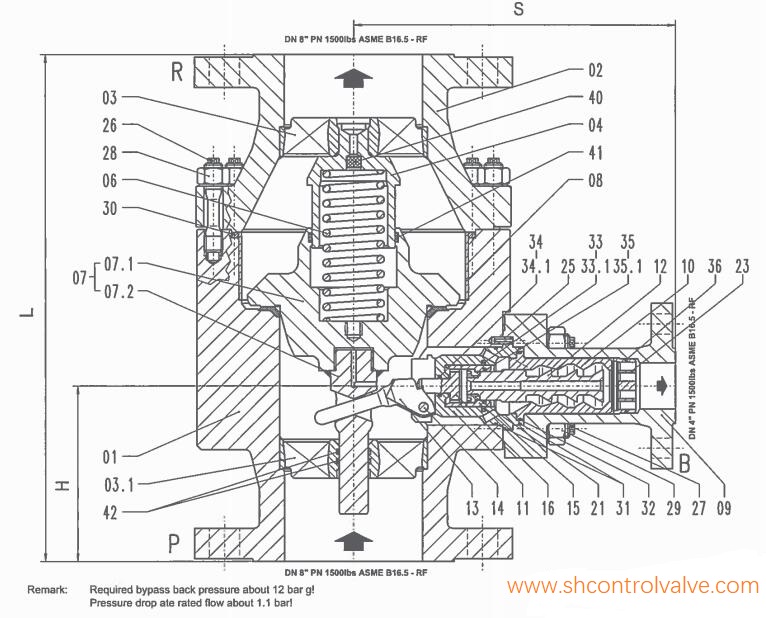

2. Casting steel, Forged steel valve body

3. Pipe connection: flange

4. Completely mechanical structure, relying on its own medium to control the valve, energy-saving, and low cost

5. The main circuit has a check valve function

6. With flow sensor function

7. The bypass is a multi-stage eddy current decompression structure, which is resistant to cavitation and erosion

8. Leakage level: ANSI V

9. DN25~DN300, PN6.4~32MPa, Class 300 ~ 2500LB

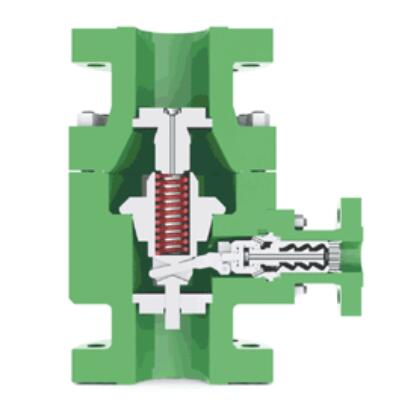

Automatic recirculation valve or ARV is a multifunctional valve. ARV Automatic recirculation valve ensures that a pre-determined minimum flow is transferred through a centrifugal pump at all times. So an automatic recirculation valve (Fig. 1) is basically a pump protection device. To avoid permanent damage (destruction) from cavitation and overheating (thermal damage) these valves serve a very important function.

The heart of the automatic recirculation valve (ARV) is a check valve disk that senses the flow rate of the fluid. The valve disk is flow-sensitive and not pressure-sensitive. It controls the fluid flow and ensures that a specified fluid volume passes through. The controlling characteristics result in a consistent and stable flow over a wide range of pressure.

At the full capacity of the valve disk, the bypass closes. Again, when the flow decreases, the action is reversed and there is an increase in the flow rate. The fluid in that situation gets into the bypass system which is controlled by the orifices and is found at the bottom of the disk.

The fluid then flows through the annulus directing it to the outlet.

The disk is lifted with an increase in the fluid flow. As a result, the bypass element which is important for the functioning of the bypass closes to limit the recirculation. This guarantees that the recirculation flow is more than the lowest volume of the flowing fluid through the pump.

So the automatic recirculation valve sets out four functions in one body. They are:

Flow perception: The valve disc of the ARV automatically perceives the main flow of the processing system. Then according to the flow, it determines the main valve and bypass valve disc position.

Another application of the automatic recirculation valve is to protect high-performance pumps during a start-up phase. In this scenario, several pumps are used in parallel with one in standby. The pump automatic recirculation valve enables the change to occur without damaging the pumps. In the Power, Paper & Pulp, Maritime, Refining, Fire protection system, and Chemical industries, an automatic recirculation valve is widely used.

The bypass fully opens when the disk closes and there is no fluid flow. It helps to protect the pump from damage that would result if the pump continued to operate with no fluid.

1.The minimum requirements of the continuous circulation system pump have nothing to do with the discharge of the process flow change system. After setting the minimum flow rate, it flows directly back to the storage tank through the orifice. Although continuous minimum flow circulation can well protect the pump, the pump must provide greater power output to ensure the system process flow and circulation flow, which will cause additional energy waste.

2.The control circulation system is composed of a check valve, a flow meter, a minimum flow control valve, and a control circulation system. The control circulation system can provide minimum flow protection. When the process flow is greater than the minimum flow of the pump, the loop is closed and no extra Of energy loss. However, the system is complex, and the control components, purchase, installation, and maintenance costs are relatively high.

3.The automatic circulation valve is equipped with a check valve, a flow sensor, a bypass control valve, and a combination of multi-stage pressure reduction. It does not require power, control systems, and wiring, and is essential for safety. It occupies a small space, minimizes the possibility of high-speed fluid failure, and reduces installation and maintenance costs. It is the first way to protect the pump in modern industrial processes.