info@shxvalve.com

info@shxvalve.com info@shxvalve.com

info@shxvalve.comTel:+86-17717520739

Email:info@shxvalve.com

Address: NO.720, Suide Road, Jiading District,Shanghai, China.

2022-11-27

Stram trap is an automatic valve that automatically drains condensate from steam to the outside of the valve body while maintaining tight contact with live steam, if necessary, allowing steam to flow at a controlled or adjusted rate. Most steam traps are capable of draining non-condensable gases while maintaining close contact with the steam.

In industry, steam is often used for heating or as a driving force for mechanical power. So the main function of a steam trap is used in such conditions to make sure that steam is not wasted.

Steam is created when water vaporizes into a gas. To make the vaporization process happen, the water molecules must be given enough energy to break the hydrogen bonds between the molecules, and this energy to convert the liquid into a gas is called “latent heat”.

The steam-based heating process uses latent heat and transfers it to a given product. When the work is complete, i.e., the steam has given up its latent heat, the steam condenses and becomes condensate. In other words, condensate does not have the ability to do work with steam. Therefore, if condensate is not removed as soon as possible, either in the steam transport piping or in the heat exchanger, the heating efficiency will be compromised.

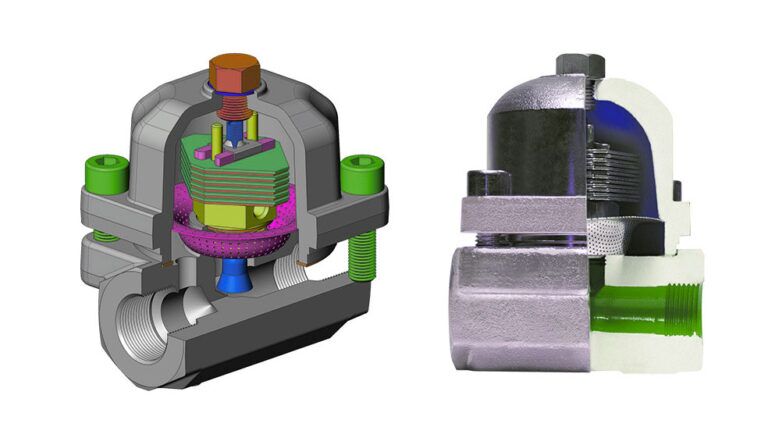

Free Float Steam Trap Features

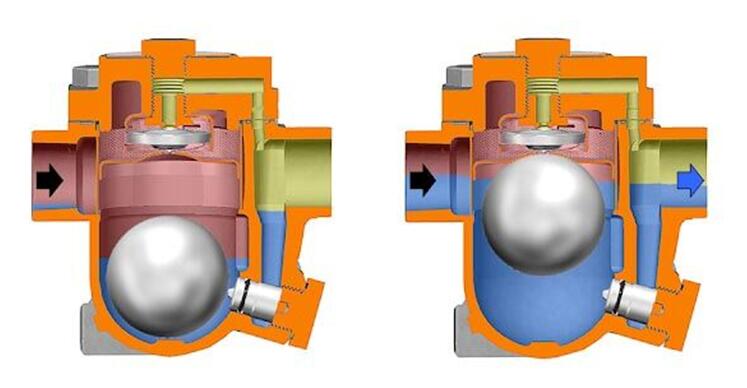

Lever float steam trap uses double holes, so that the pressure of the valve core is relatively reduced when the valve is opened, so as to obtain a large displacement. When working, the float floats up and down with the change of the liquid level in the valve chamber, driving the lever to open or close the seat. As the valve seat hole is below the water level of the condensate water, the water seal is formed, and the water and steam are separated naturally to achieve no steam leakage.

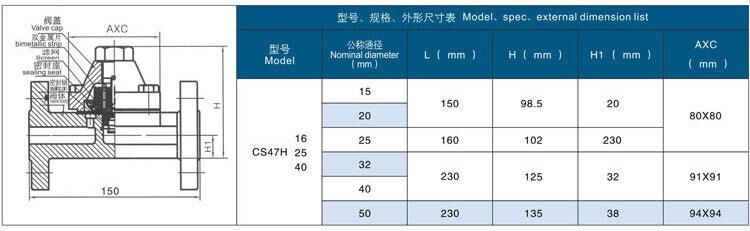

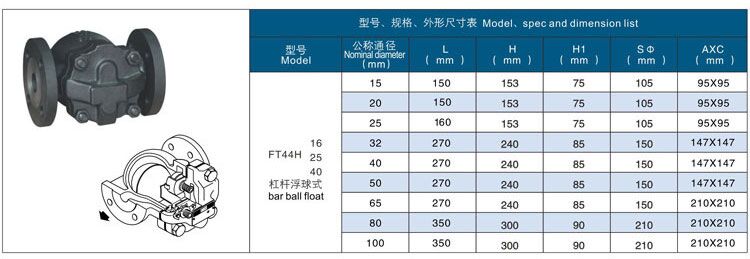

FT44H Free Float Ball Steam Trap Dimension

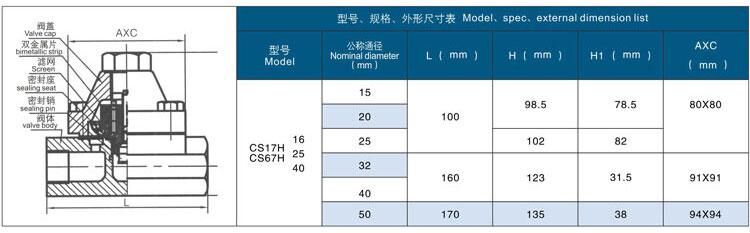

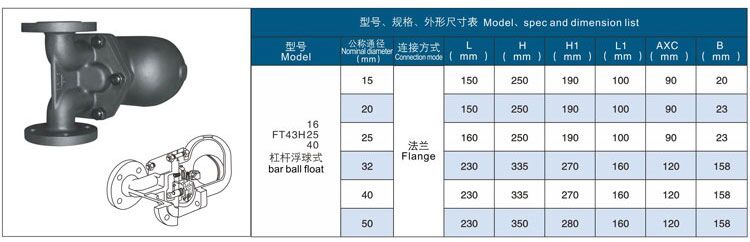

FT43H Free Float Ball Steam Trap Dimension

The steam leakage rate is less than 3%, the back pressure rate is 75%, there are more connections, and the sensitivity is not as good as that of the free float type trap. Because inverted bucket traps rely on the upward floating force of steam to close the valve, they are not suitable for use when the differential pressure is less than 0.1 MPA.

According to the principle of phase transformation, the disc thermodynamic steam trap depends on the different thermodynamic principles of velocity and volume change when steam and condensed water pass through, so that the upper and lower pressure difference of the valve disc is generated, and the valve disc is driven to open and close the valve. Because the working power of the thermal steam trap comes from steam, so the steam waste is relatively large. Simple structure, water shock resistance, the maximum back of 50%, noise, frequent valve work, short service life.

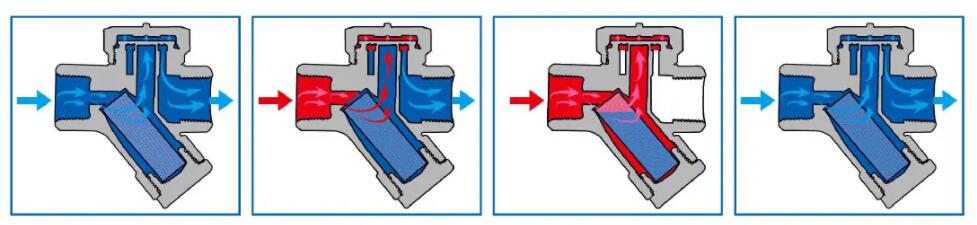

Thermostatic traps are based on the balance of steam pressure and the internal pressure of the thermostatic membrane capsule, which is filled with a special liquid whose saturation temperature is slightly lower than that of steam at any pressure.

In the start-up position, the steam trap opens fully to remove air and drain condensate. When the temperature reaches the pressure-dependent saturated steam level, the vaporization of the liquid inside the thermostatic capsule membrane generates a differential pressure that causes the orifice to close. As the condensate cools, the condensation of the liquid reduces the internal pressure of the membrane. The resultant differential pressure will benefit the external pressure that acts on the membrane by retracting and opening the orifice, which allows the condensate to drain and the cycle to continue.