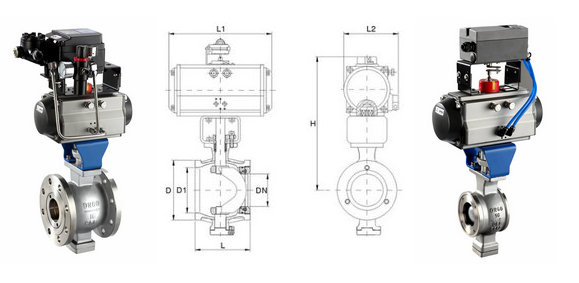

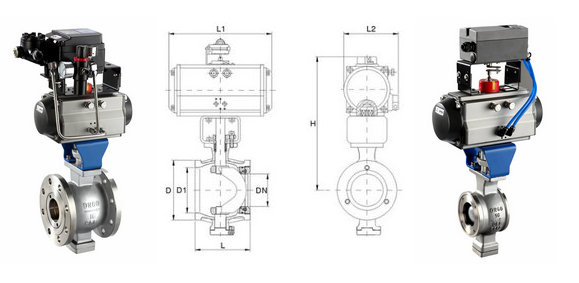

Wafer type Pneumatic segment ball valve introduction:

Wafer type Pneumatic segment ball valve is a ball core for the v-shaped structure of the regulating ball valve, the segment ball valve core is a quarter of the ball shell, open v-shaped notch, flow capacity, with shear force, can close the characteristics of tight.Wafer type Pneumatic segment ball valve according to the v-shaped Angle formed between the v-ball core and the pipeline, with the rotation of the ball, Wafer type Pneumatic segment ball valve can use the change in the middle of the open area for flow regulation, and can cut off impurities in the fluid and close, suitable for pulp, mortar, viscous fluid control.

Wafer type Pneumatic segment ball valve application:

Wafer type Pneumatic segment ball valve application:

Wafer type Pneumatic segment ball valve has good cutting performance and regulating performance, widely used to control pulp, sewage, containing fiber and solid particles suspended medium and high temperature steam, dry gas and other media, especially Wafer type Pneumatic segment ball valve is a single sealed ball valve, is not suitable for two-way use.

Wafer type Pneumatic segment ball valve features:

1, Wafer type Pneumatic segment ball valve has approximately the same ratio of the inherent flow characteristics and linear characteristics;Double bearing structure, small starting torque, excellent sensitivity and speed;

2, Wafer type Pneumatic segment ball valve ball core with v-notch, in the closing, v-notch and hard seal seat produce a strong shear force, can be cut off containing fibrous media, and effectively prevent the ball core stuck;

3, Wafer type Pneumatic segment ball valve has a v-type spool structure, even in the working conditions of small flow or high viscosity medium, but also in the whole range, to ensure the accuracy and accuracy of the control;

4, Wafer type Pneumatic segment ball valve is generally used with valve positioner and other accessories, suitable for a variety of adjustment occasions, rated flow coefficient, sensitive adjustment performance, adjustable range can be installed vertically.

Wafer type Pneumatic segment ball valve technical parameters:

Nominal size: DN25 ~ DN300(mm)

Nominal pressure:PN1.0, 1.6, 2.5, 6.4MPa

Connection method: flange type, pair type

Drive type compressed air: 4-7bar, with manual device available

Temperature range:soft seal:-30 ~ 180℃;Hard seal :-40 ~ 450℃

Spool structure: v-notch ball core

Sealing material:PTFE,RPTFE, metal seal

Body material: carbon steel WCB, stainless steel 304, 316, 316L

Action form: single action (spring return), double action (air on air off)

Control mode: switch two-digit cut off, precision adjustment 4-20mA analog signal (both optional explosion-proof)

Wafer type Pneumatic segment ball valve function:

Wafer type Pneumatic segment ball valve according to the sealing performance is divided into soft seal and hard seal, soft seal is generally used in the low pressure room temperature, and hard seal can be used in the room temperature and high temperature and high pressure pipeline.According to the control mode is divided into external regulation and switch to cut off type, type switch mode can be divided into the form of the function of single and double acting type, while the external regulation should choose double-acting, unique advantage of single-acting actuator is once air loss of air pressure or the pipeline failure cases, Wafer type Pneumatic segment ball valve will be in accordance with the requirements of the control system of automatic reset to the state of the valve closed or open.

info@shxvalve.com

info@shxvalve.com info@shxvalve.com

info@shxvalve.com