Pneumatic flush tank bottom ball valve introduction:

Pneumatic flush tank bottom ball valve is a special structure of the discharge valve, the seat and the end flange close to the material retention, with compact structure, excellent sealing performance and other characteristics,Pneumatic flush tank bottom ball valve often used in fine chemical, pharmaceutical, chemical industry on the reaction pot, can also be used in fine soft particle medium transport.Pneumatic flush tank bottom ball valve adopts PPL or M sealing material, which is more wear-resisting and temperature-resistant. It is an ideal product for discharging materials in toothpaste industry and vacuum paste pot.

Pneumatic flush tank bottom ball valve features:

Pneumatic flush tank bottom ball valve features:

Pneumatic flush tank bottom ball valve can also be lined with FEP, the internal runner and other parts are fully lined with FEP material, can effectively isolate the erosion of the medium to the valve body, Pneumatic flush tank bottom ball valve has a very high chemical stability, suitable for corrosive gas, liquid and any other corrosive nature of the medium in the pipeline.

Pneumatic flush tank bottom ball valve parameters:

Nominal diameter: DN25 ~ DN100(mm)

Nominal pressure: PN10 ~ 25, CLASS 150

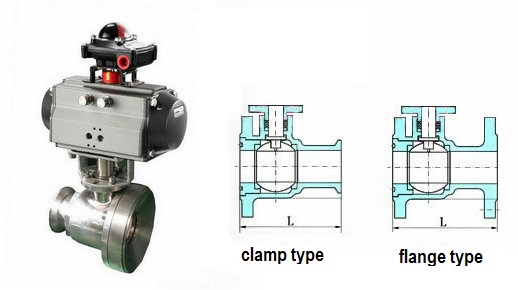

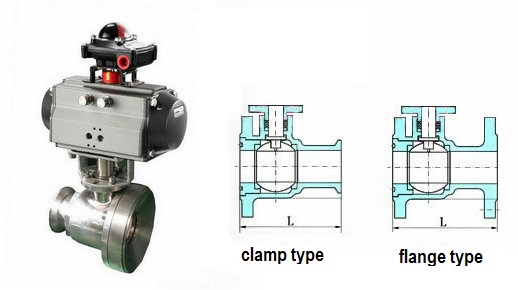

Connection form: flange type, clamp type

Structural form: straight through

Actuated air source control: (compressed air 4-7bar)

Temperature range: -20℃ ~ 150℃

Spool structure: V - type, O - type spool

Body material: cast steel (WCB), stainless steel (304, 316, 316L)

Sealing materials: PTFE, reinforced PTFE (PPL), flexible graphite

Use medium: pharmaceutical, chemical reaction pot and fine soft particle medium

Control mode: switch type (two-digit cut off), control type (4-20ma signal)

info@shxvalve.com

info@shxvalve.com info@shxvalve.com

info@shxvalve.com